Cargill improves lab safety with Precision

Cargill was founded in 1865 as a single grain warehouse in Iowa, U.S, and has since grown to become a global partner connecting people around the planet and across the agricultural supply chain.

We took some time to talk to Jack Sismour, a Project Engineer at Cargill, to get his thoughts on his lab’s Precision generator.

We took some time to talk to Jack Sismour, a Project Engineer at Cargill, to get his thoughts on his lab’s Precision generator.

Typically, what is the focus of your GC analysis?

QA/QC for our epoxy resin manufacturing plant.

What PEAK Scientific generators do you have in your laboratory and what instrument(s) do they supply?

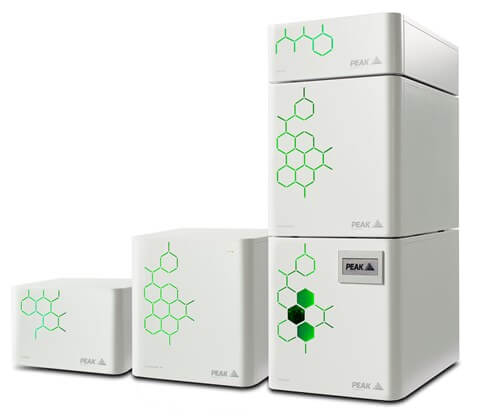

We have the full stack of Precision generators - H2, N2, Zero Air, and Compressor for our GCs.

Can you explain the safety benefits Precision has brought to your lab?

We’ve been able to reduce the amount of hydrogen stored in the lab at any given time, as well as the elimination of ergonomic issues with large storage tanks. Another benefit is that the continuous gas supply yields improved the availability of analytical processes.

What prompted you to choose a PEAK Precision hydrogen generator for your analysis?

We went with PEAK because we have other PEAK generators in labs within our company and they are trusted across the board.

What has been the key benefit of deploying PEAK's Precision for your analysis as opposed to your previous gas supply solution?

The biggest change has been the drastic improvement in overall lab safety by eliminating large tanks.

How would you describe your PEAK generator purchasing experience in terms of speed of response, ease of ordering, catering for your needs and timing of delivery?

One word: Excellent.

Would you recommend PEAK Scientific generators to other laboratories? If yes, what would be your main reason for recommendation?

Yes, it’s a straight-forward installation and the generators have a very operator friendly design.