Gas Cylinder Costs

A number of labs are switching from gas cylinders to an in-house, on-demand gas generator to supply gas to their analytical instrument. However, some laboratories are still using the more traditional bulk supply methods, which comes at an increasingly high cost.

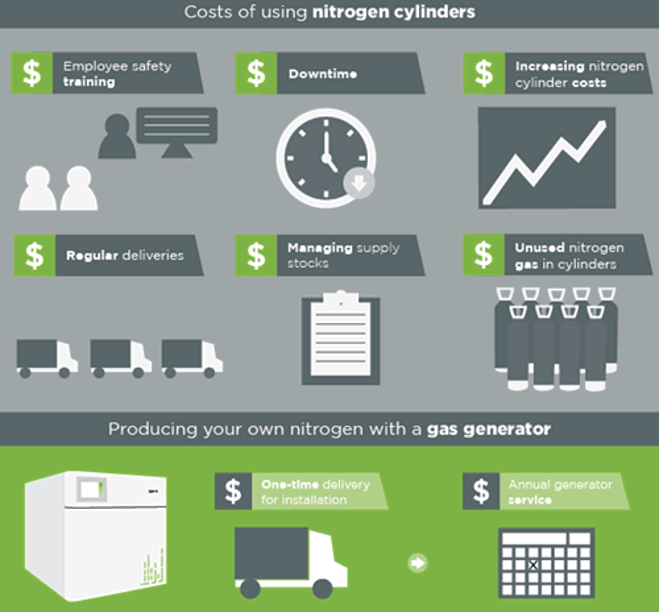

Labs relying on gas cylinders for their instrument supply may be unaware of the additional, often hidden, gas cylinder costs. It can also be the case that bulk gas suppliers offer what may appear to be an affordable monthly contract which, when compared to on-site gas generation, quickly adds up over time, increasing the lab's total expenses.

So, what is it that you really pay for with a gas cylinder?

Supply Planning & Fluctuating Gas Cylinder Costs

Bulk gas supply requires regular pre-planning to settle contracts and ensure the gas cylinder deliveries arrive on time, which can still be subject to inevitable delays leading to supply issues. Most bulk gas suppliers will also charge a fee for the rental of the cylinder, adding more costs over the course of one year. On top of all these logistical charges, labs might be faced with fluctuating gas cylinder costs which may vary depending on the supply and demand of the gas.

Installation Work

The storage of high-pressure gas cylinders requires careful planning due to the safety regulations around their operational use. For instance, a gas cylinder needs to be placed in a sheltered but well-ventilated area. Gas cylinders also take up a lot of space, particularly if using multiple cylinders, they will also need to be securely fenced to limit access to the cylinder. In the event that large bulk storage is required, labs might also need to seek planning permission from their local authorities for approval of their ground works.

Staff Training & Labor

Highly pressurized gas cylinders can pose potential safety risks if mishandled, so labs running their analytical equipment with a gas cylinder need to invest in staff training to ensure the cylinders are handled correctly. Cylinder containers also need to be replaced and inspected regularly by lab personnel to ensure they are safe to use. This adds an extra ongoing task for workers, potentially resulting in a disruption to the day’s workflow.

Unused Gas

Gas contained inside a gas cylinder can collect impurities and it is therefore advised that the remaining 10% of gas is not used for analysis. Nevertheless, due to differential pressure, it’s not possible to use up the gas inside a cylinder completely. This means around 10% of the gas cannot be accessed and litres of unused gas which was paid for goes to waste.

Eliminate Gas Cylinder Costs with an In-House Nitrogen or Hydrogen Gas Generator

Opting for an on-site nitrogen or hydrogen gas generator can eliminate the overwhelming expenses associated with gas cylinders. With an on-site nitrogen or hydrogen gas generator, you can:

- Increase lab productivity without the hassles of ordering cylinders

- Cut down on additional costs by producing your own gas, on-demand

- Eliminate the dangers associated with manhandling gas cylinders

- Have peace of mind, knowing you will never run out of gas

The operational cost behind in-house gas generation is extremely low, with only a one-time order for the gas generator delivery and installation, and an annual preventive maintenance check. Considering these savings, labs using a gas generator can expect to see a return on investment within the first year of ownership – a major benefit to the overall operational expenses of a lab.