Hydrogen as carrier gas - hydrogen generator in the petrochemical industry

Helium is often used as a carrier gas for GC-MS, but with the global shortage of helium, and significantly increasing prices, more and more users are choosing hydrogen as an alternative carrier gas. Hydrogen generators can produce hydrogen that meets application requirements by electrolyzing pure water. Hydrogen as a carrier gas also has many potential advantages, such as faster analysis times, higher column efficiency, and better sample resolution.

In cooperation with Mr. Chen Song of Sinopec Beijing Research Institute of Chemical Industry, BYK has developed the application of hydrogen instead of helium as carrier gas in petrochemical methods--- “Determination of Phosphine and Arsine in Propylene by GC-MS using Hydrogen and Helium as Carrier Gas”, which has been published in the Journal of Petrochemical Technology.

Customer-site Agilent7890B/5977B (HES) type hydrogenic combined instrument, PEAK Precision Trace hydrogen generator

Customer-site Agilent7890B/5977B (HES) type hydrogenic combined instrument, PEAK Precision Trace hydrogen generator

In this paper, hydrogen and helium were used as carrier gases, and the gas-quality combination (GC-MS) analysis method of trace phosphine and arsenic in polymer grade propylene raw materials was established, and comparative analysis was carried out.

Instrument information

Instruments and Reagents

Instrument: 7890B/5977B (HES) GC-MS, Agilent, USA; flash vaporization system and dynamic dilution system, Beijing Genesys Tech Analytical Technology Co., Ltd., flash vaporization temperature 80~160℃, dilution ratio 1:200, pipeline and cavity passivation.

Carrier gas: Purity greater than 99.999% hydrogen, trace hydrogen generation device, PEAK Gas Instruments Trading Co., Ltd. Purity greater than 99.999% helium, 40L cylinder gas, Dalian Date Gas Co., Ltd.

Standard gas: 0.995mL/m3 phosphine, 0.987mL/m3 arsine, balanced Gas Helium, Dalian Date Gas Co., Ltd.

Analysis of results

1. Retention time

Hydrogen carrier gas and helium carrier gas were used analysis.

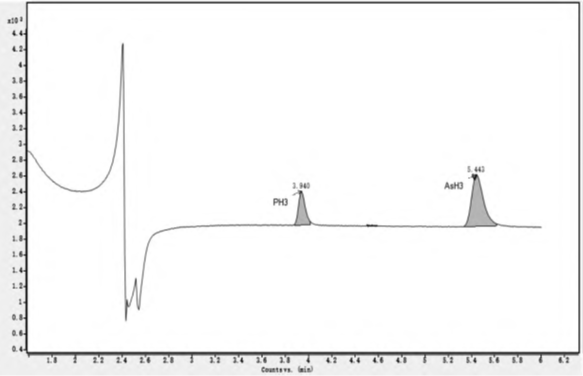

The results showed that when hydrogen was used as the carrier gas, the peaking time of the target was within 8 minutes under the condition of baseline separation, which was shorter than that of helium as the carrier gas, and the analysis speed was faster. See Figure 1.

Fig.1 Selected ion spectra of hydrogen carrier gas phosphine and arsine on PLOT U column

Fig.1 Selected ion spectra of hydrogen carrier gas phosphine and arsine on PLOT U column

This is because at the same temperature and pressure, the viscosity of hydrogen is half that of helium. While the diffusion of the sample in the two gases is similar, which means that hydrogen passes through the gas chromatography column faster, the analysis speed is faster.

2. Linear range and linear relationship

In this paper, the external standard correction quantitative curves of phosphine and arsenic are plotted.

As shown in the following table, the phosphine and arsenic content were in the range of 0.005-0.995 mL/m3, and hydrogen and helium had a good linear relationship on GC-MS when they were used as carrier gases, and their correlation coefficients were greater than 0. 999.

Table 1. Phosphine and arsine calibration curve equation and linear correlation coefficient

| Sample | External Standard Curve | Linear Related Coefficient | Linear Range (mL/m3) |

|---|---|---|---|

| PH3 (H2) | y=9.97 x 10-2x + 4.18 x 10-2 | 0.999 | 0.009-0.995 |

| AsH3 (H2) | y=1.66 x 10-3x + 6.31 x 10-3 | 0.999 | 0.005-0.987 |

| PH3 (He) | y=9.57 x 10-2x + 7.36 x 10-2 | 0.999 | 0.006-0.995 |

| AsH3 (He) | y=1.78 x 10-3x + 4.55 x 10-3 | 0.999 | 0.004-0.987 |

3. Precision, accuracy and detection limits

The precision, accuracy, and minimum limit of detection (LDL) of the method are examined by relative standard deviation (RSD), scaling recovery rate, and signal-to-noise ratio (S/N=3).

From Table 2, it can be seen that the RSD of the two carrier gas GC-MS methods is within 4.0%, the standard recovery rate is in the range of 90%-110%, and the minimum detection limit is less than 10 μL/m3.

Table 2. Recovery, relative standard deviation, minimum detection limit

| Sample | Theoretical Value | Measurements (average of 6 times) | Recovery Rate (%) | RSD | %LDL |

|---|---|---|---|---|---|

| PH3 (H2) | 0.099 | 0.106 | 106.1 | 2.81 | 0.009 |

| AsH3 (H2) | 0.098 | 0.095 | 96.9 | 2.94 | 0.005 |

| PH3 (He) | 0.099 | 0.098 | 98.9 | 3.15 | 0.006 |

| AsH3 (He) | 0.098 | 0.097 | 98.0 | 3.74 | 0.004 |

Conclusion

The results show that the GC-MS method using hydrogen as the carrier gas has no significant differences with helium in terms of qualitative and quantitative analysis, method precision, accuracy and minimum detection limit.

Moreover, after the actual sample test, the GC-MS analysis method of hydrogen as carrier gas can fully meet the requirements of the detection and analysis of phosphine and arsenic content in polymer grade propylene raw materials. And the GC-MS method of hydrogen as carrier gas is lower than that of helium as carrier gas.

The above content is referenced from: Chen Song: Determination of phosphine and arsenic in propylene by combining hydrogen and helium carrier gas. Petrochemical Technology, 2022, Issue I: 33-35

PEAK's Precision Hydrogen Gas Generator

PEAK’s Precision H2 Trace series hydrogen generators can provide ultrapure hydrogen for GC-MS. This generator uses proton exchange membrane (PEM) technology to electrolyze water to produce hydrogen, and uses a pressure swing adsorption (PSA) drying system to ensure hydrogen purity of 99.999999%.

In terms of hydrogen safety, the generator has a leak detection function and a fault protection mechanism to ensure that laboratory users can use hydrogen safely.

A hydrogen detector (optional) can also be installed in the GC column oven, and in the event of a hydrogen leak, the entire system (including GC-MS) automatically stops to ensure safety.