Choosing laboratory gas generators: How to decide

When it comes to deciding which gas generator is best for your lab there are some considerations lab managers must make. There are two main technologies used to generate nitrogen from air: membrane systems and Pressure Swing Adsorption (PSA).

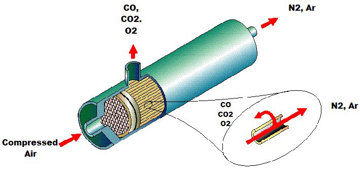

Membrane Nitrogen Generator Technology

As a result of selective permeation across the membrane wall, nitrogen is separated from atmospheric air. Gases that are "fast" (oxygen, carbon dioxide, and water vapor) permeate the membrane wall much faster than gases that are "slow" (nitrogen).

In the selective permeation process across the membrane wall, nitrogen is separated from the atmospheric air source. The original gas mixture is separated into two streams: the permeate and the product. As a result of the permeation process, oxygen, carbon dioxide, and water vapor are combined and vented.

Membrane technology illustration

The lower the flow rate passing through the membrane the higher the purity of nitrogen is achieved. The purity can be further enhanced by increasing the temperature.

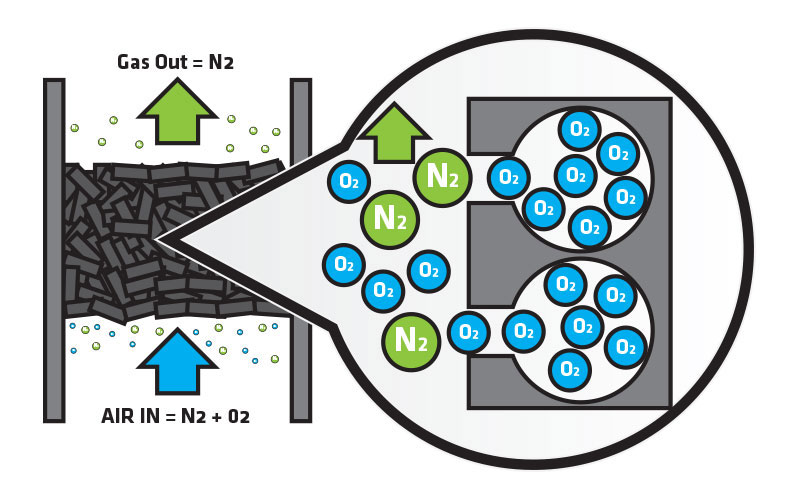

Pressure Swing Adsorption Technology

The other option, Pressure Swing Adsorption, cycles gas at high and low pressure, flushing compressed air through a bed of carbon beads, also known as a Carbon Molecular Sieve CMS. Nitrogen molecules are allowed to pass through the carbon bed but the oxygen and carbon dioxide molecules are too large to pass through and are vented off. PSA generators can be scaled up to provide very large quantities of nitrogen gas for entire labs or for manufacturing and process industries.

PSA technology illustration