The majority of laboratories worldwide use gas cylinders to supply their analytical instruments, sample prep systems and other lab applications.

The cylinder suppliers often have long-term agreements with their customers, offering a solution that is relatively cheap and can easily be built into lab overheads. Many lab managers don’t think past this point. Gases are required for analyses, and an established solution is in place which is paid along with the electricity and heating bills so the cycle of cylinder orders, deliveries, collections and invoice payments continues.

Gas generators have been on the market for over 20 years and offer a safe, convenient and cost-effective alternative to cylinders. An LC/MS using 32 liters per minute (1.13 CFM) of nitrogen for 8 hours per day will consume around 5.5 million liters (194,230 ft3) of Nitrogen in 1 year of operation. This is equivalent to 620 cylinders.

What also needs to be factored into the costs required to satisfy these gas needs is the time taken for ordering, cylinder installation, processing of paperwork and a whole host of other factors that use employee time.

Now if we take the example above and look at the costs associated with the purchase, installation and running costs of a generator which produces 32 liters per minute (1.13 CFM) of nitrogen to supply the LC/MS, we have seen in our experience that within 1 year or better, we would already have paid back the cost of the generator with money to spare. From that point onward, the only costs associated with the generator are maintenance and running costs (electricity), which are negligible compared with the costs associated with cylinder deliveries, rental and administrative time.

Another advantage of using gas generators as well as convenience is their safety. Cylinders contain a large volume of stored gas which can present a danger if released rapidly into the lab environment. In the case of hydrogen, there is the additional explosion risk. Once the level of hydrogen reaches 4.1% by volume in air, the lower explosion limit is reached, meaning that ignition of the gas could cause an explosion. A large hydrogen cylinder containing 9,000 liters (318 ft3) of compressed hydrogen contains enough gas to reach the LEL for a 220 m3 (7,770 ft3) room.

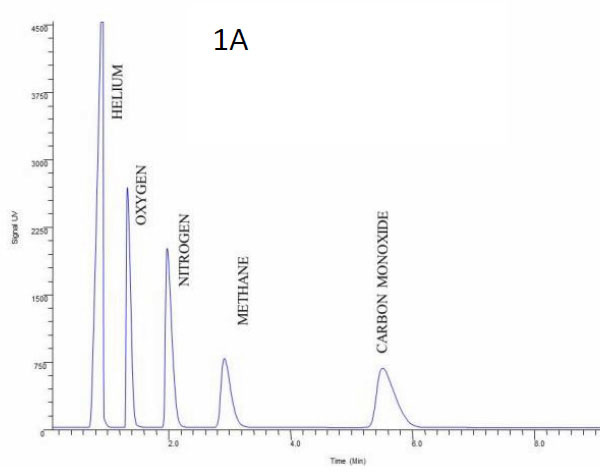

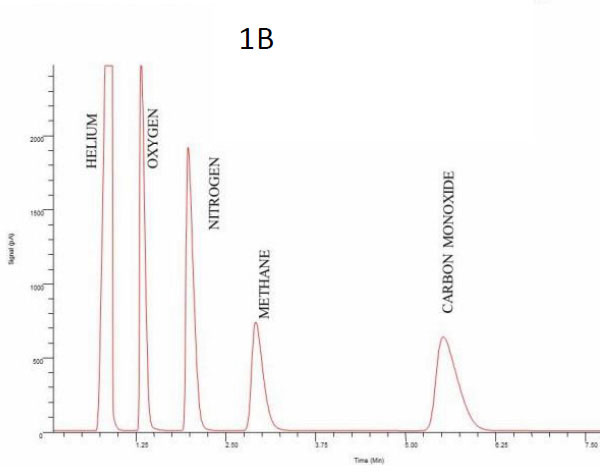

A hydrogen generator offers a safe alternative, producing enough hydrogen to supply a number of applications, without the requirement for bulk storage of gas. Using a GC-TCD, we analyzed a gas mixture of oxygen, nitrogen, methane and carbon monoxide in balance helium. Results showed no difference in performance by either gas, showing that a hydrogen generator is a safe alternative to cylinders while offering excellent performance.

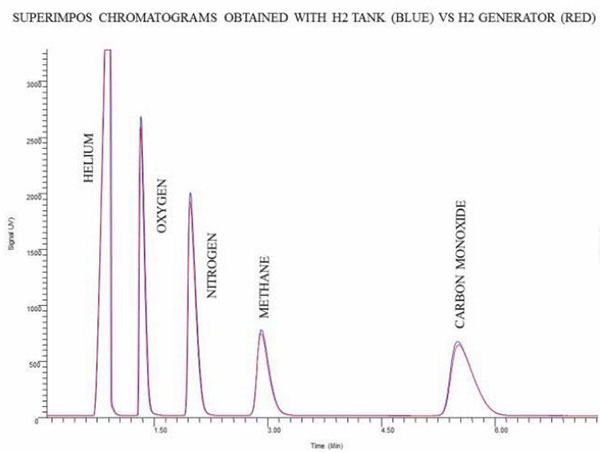

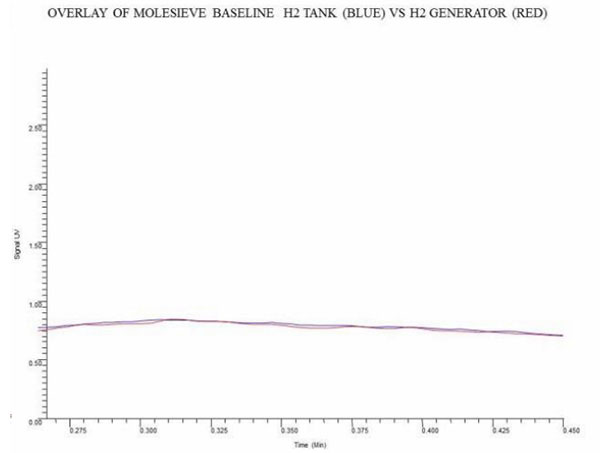

Figures 1A and 1B show results of analysis using hydrogen from the generator and a hydrogen gas cylinder. Figure 2 shows an overlay of results from the generator and cylinder demonstrating identical performance of the two gas sources. Figure 3 shows TCD baseline.

Figure 2: Overlay of gas analysis results using Cylinder (blue) and hydrogen generator (red).

Figure 3: GC-TCD baseline results using cylinder (blue) and hydrogen generator (red).

Results of the analysis show that a hydrogen generator can be used to produce carrier gas that will give comparable results to cylinders without the associated risks of storing large volumes of hydrogen in the lab.

Ed Connor DR.SC. is GC-MS Application Specialist, PEAK Scientific, Inchinnan Business Park, Scotland, UK . Prior to joining PEAK in February 2013, Ed completed his Dr.Sc. at ETH Zurich in Switzerland using GC-MS to look at herbivore induced plant volatiles and their interaction with beneficial insects. He then joined the University of Zurich where his work focused primarily on volatile collection methods and analyses using GC-MS and GC-FID . +44 141 812 8100, econnor@peakscientific.com

Find out more about PEAK Scientific's hydrogen, nitrogen and zero air generators for GC and LC-MS or contact us.