Why switch from helium to hydrogen gas for GC?

Reliable and convenient

As a non-renewable resource, helium gas is becoming increasingly scarce, leading to supply shortages and an increase in costs for numerous industries, including analytical laboratories. For labs relying on helium, a lack of supply can cause delays in sample analysis and a general disruption to day-to-day workflow.

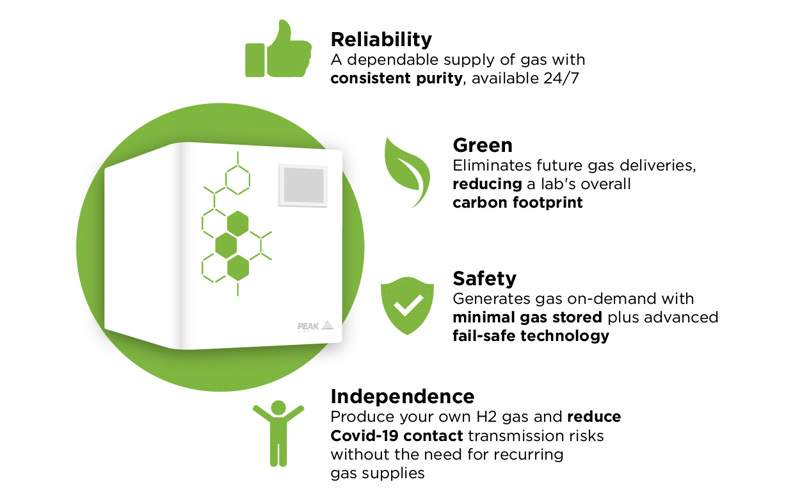

Working with an in-house hydrogen generator, on the other hand, is a more reliable, inexpensive and convenient way of performing GC analysis. With a hydrogen generator, labs can produce their own high purity carrier gas supply without having to depend on cylinder deliveries or go over their budget due to a sudden spike in helium prices. Once installed, a hydrogen generator stays in your lab, eliminating all the logistical hassles associated with scheduling helium gas orders, planning cylinder changeovers and installation. A gas generator provides peace of mind, knowing you have access to a constant supply of hydrogen gas and not having to worry about running out of carrier gas mid-analysis.

Safe

Unlike a pressurized gas cylinder, a hydrogen generator does not store high volumes of gas which could pose a potential safety hazard. When working with a gas cylinder, laboratory staff have to be on the lookout for any signs of leaks or damage on the cylinder in order to prevent any explosion or fire risk due to such high volumes of pressurized gas. With a hydrogen generator, however, labs can minimize these risks. A hydrogen generator will only generate the amount of hydrogen gas required to meet instrument need, meaning very small volumes of gas are stored at any one time. Performing analysis with a hydrogen generator also eliminates the requirement of transporting cylinders which could potentially be dangerous if not handled carefully.

Labs working with hydrogen generator can also restrict outside contact and limit Covid-19 contact transmission. Once installed, a hydrogen generator can be operated fully operated by a lab’s members of staff, allowing labs to eliminate contact with third party suppliers.

Beyond the absence of pressurized gas storage, a hydrogen generator comes equipped with advanced built-in fail-safe technology. These safety features prompt the hydrogen generator to shutdown in the unlikely event of a leak, maintaining safety in the lab.

Environmentally friendly

A hydrogen generator only requires a one-time delivery for installation. From then on, your hydrogen generator stays in the lab, eliminating regular cylinder deliveries, thereby reducing your lab’s overall carbon footprint.

Another environmentally friendly consideration is the process by which hydrogen gas is generated. A hydrogen generator produces hydrogen gas from deionized water, offering a renewable alternative to helium gas. Producing hydrogen gas from deionized water is also in contrast to the energy-intensive process of steam reformation methane, which is the most common method of obtaining cylinder hydrogen.

Shorter run times

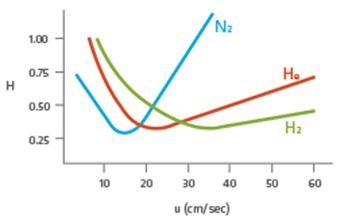

Speedier analysis is another advantage to using hydrogen gas instead of helium. Hydrogen gas has a higher optimal linear velocity than helium, therefore in many cases increasing a lab’s throughput by improving analysis speed.

Van Deemter curve

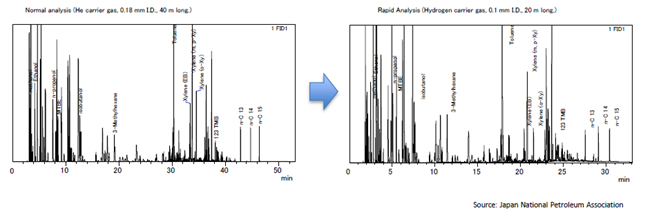

As demonstrated in the gasoline analysis of Fig. 1, the analysis time was shortened with hydrogen carrier gas. Since hydrogen gas can flow gas at a lower supply pressure than helium, it is suitable for high speed analysis using a narrow bore capillary column.

Fig. 1

Making the switch

If you’re looking to convert to hydrogen gas, you need to consult the GC Method list to confirm your method can indeed use hydrogen gas as an alternative to helium. It’s also important to refer to your method translation software for a simulation of the effect of changing carrier gas. There are GC instruments facilitating this conversion, such as Nexis GC-2030 by Shimadzu, which allows GC practitioners to switch carrier gas in the same sample run without adjusting any setups. You can refer to our step-by-step guide for more information on converting carrier gas.

For a safe and reliable source of hydrogen gas, Peak Scientific’s Precision Hydrogen Trace range of hydrogen generators make the switch even easier with user friendly touchscreen operation. Specifically designed for GC and also suitable for FID, Precision Hydrogen Trace is available in various flow rates for all lab gas requirements, all available at a maximum purity of 99.99999%. Offering greater safety, Precision Hydrogen Trace comes in a compact and space-saving design, maximizing your lab’s floorspace.

Although helium is a popular carrier gas choice in GC, the difficulty in obtaining the gas has made more labs reconsider their gas supply, seeing an increase in the shift of carrier gas from helium to hydrogen gas. When all aspects are considered, it is easy to understand what’s driving the switch: the unrivalled reliability and peace of mind that can only be provided by a hydrogen generator.

References: