Pressure Swing Adsorption, on-site nitrogen gas generation

One of the core technologies in many nitrogen gas generators today is Pressure Swing Adsorption (PSA), using Carbon Molecular Sieve (CMS) adsorbent. In the process of PSA nitrogen generation, a highly efficient CMS method is used to generate a high purity nitrogen gas from a compressed air source.

What are PSA and CMS?

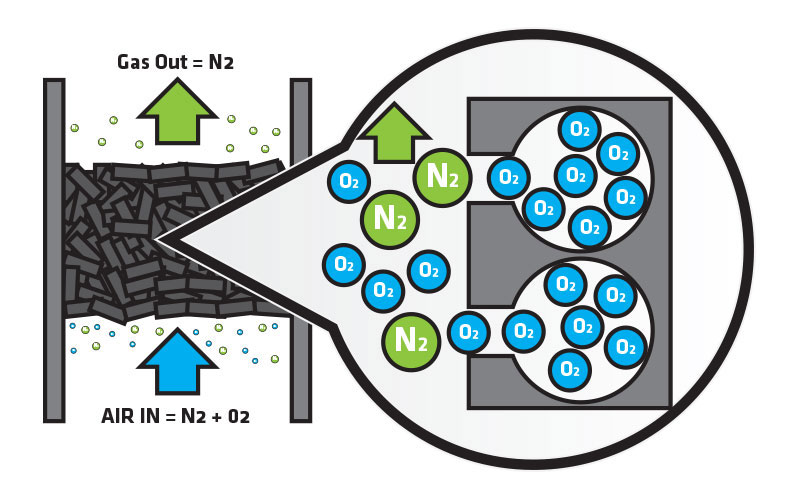

PSA is an air separation technique that allows the separation of a gas mixture into its individual components by using a solid medium, in this case CMS, to which part of the gas mixture preferentially adsorbs under pressure.

The CMS is essentially a bed of small carbon beads. When a nitrogen purification column packed with CMS is pressurized with atmospheric air (mainly consisting of nitrogen, oxygen and argon) and moisture, oxygen and moisture are adsorbed by the carbon beads whereas nitrogen is not. This occurs because of the angstrom size of nitrogen and oxygen molecules – the CMS pores are exactly the right size to allow oxygen to enter and adsorb, whereas the nitrogen molecules are too large and pass through the purification column.

PSA using CMS diagram

The PSA process consists of a two stage cycle;

- The Adsorption stage, where oxygen, H2O, and CO2 molecules in compressed air are adsorbed into the porous structure of the CMS whilst nitrogen molecules pass through the column and into a storage vessel.

- The Regeneration stage where the pressure normalizes via rapid depressurization and the adsorbed molecules are vented to the atmosphere.

This process requires a constant temperature, which is as close to an ambient as conditions will allow (20-25 degree C).

PEAK Scientific produce several PSA generators including several of our best-selling Genius series to our Precision Nitrogen and Hydrogen generators for GC as well as our whole of lab solution, i-FlowLab.

Related Post: Read about the advantages of PSA nitrogen generators here.

PEAK Scientific laboratory gas generators